Superior quality, Good service, Timely delivery and Sincere Co-operation of Suppliers, Stockist & Importers Of Raw Materials like Pipe Fittings, Flanges, Pipes, etc.

Products Range

Welcome To

Multi Metals (India)

Multi Metals (India), with its beginning since two decades, has been contributing to the growth and development of Oil & Energy Sector.

We serving the EPC Contractors, Promoting Companies with quality piping products such as Pipes & Tubes, Flanges & Pipe-Fittings in the field of Oil & Gas, Refining & Petrochemical, Pipeline, Power Generation, Shipbuilding, etc.

Our Services

Delivery

Flexible INCO terms like EXW, CIF, CNF and DDU exclusively for door deliveries for both inland and Coastal carriers can be provided.

Third Party Inspection

Third Party Inspection services refers to independent inspection services that are provided by inspection agencies.

Packing

Pipes & Tubes are loose or in bundles tightened with Iron Strips. Special packings: Metal or Wooden Cases, Pallets etc.

Ends & Surface

All tubes are supplied with clean, square cut ends. Deburring and/or chamfering can be carried out on request.

Certificates & Markings

Pipes & tubes are supplied with 3.1 certification as per EN 10204.

Competitive Prices

We offers a commendable range of Pipe Fittings, Flanges & Pipes for the prestigious clients with competitive price.

Industries We Serve

Oil And Gas

Petrochemical

Nuclear Power & Defence

LNG

Desalination

Mining & Minerals

What clients say.

Multi Metals (India) have always been our preferred supplier for Inconel Pipe Fittings which have excellent quality with prompt delivery and competitive prices.

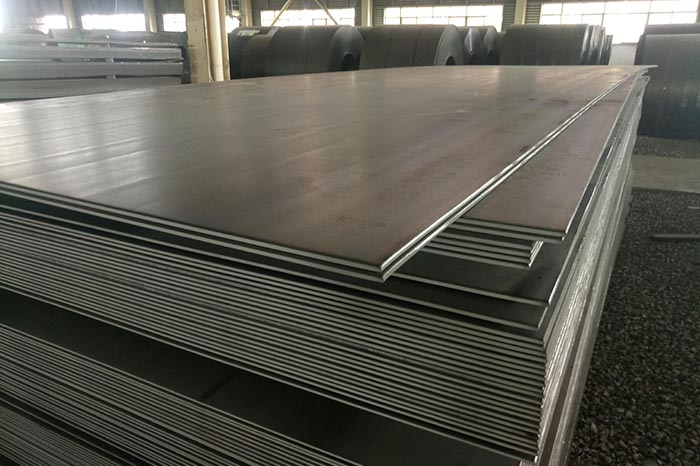

We have been sourcing Duplex Steel Sheets for the past 4 years from Multi Metals (India). They supply high quality products and provide third party inspection certificates on request.

Multi Metals (India) have always helped us by providing us customized solutions for our project needs at the most affordable prices with on time delivery schedules.

Impressed with their high quality Carbon Steel Pipes. You can trust Multi Metals (India) when it comes to price, consistency and performance.

We are honoured to be partnered with Multi Metals(India) as one of the leading suppliers of Stainless Steel Plates with superior material quality, regular supply and timely delivery.